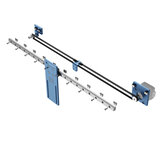

Upgraded 3018 Pro CNC Router Offline Engraver DIY 3Axis GRBL Engraving Machine Woodworking Router

Customer Reviews

- All Reviews (135)

- Image (31)

- Video (0)

A part of the review has been auto-translated.

-

BG381550371CH16/11/2021

BG381550371CH16/11/2021I can confirm receipt to day. (The button [Confirm Receipt] is not visible, instead of this [Buy Again] is on this button. Avaiting again response of my question for the best / strongest possible laser for this machine. They are several lasers but without a compatibity remarked.

Comments (2)Show Original -

05/12/2021

The machine frame is very solid, although it is made from metal and plastic parts. The linear rods are 10 mm in diameter, not 8 mm like the ones from 3D printers. It uses a custom made ATmega328p based control board running GRBL 0.9j. I like that it has an offline controller which allows me to load Gcode from SD card and keep my computer away from the CNC. In the product description, they say you should not upgrade to GRBL 1.1. I did that and the CNC works smoothly (I flashed the precompiled GRBL 1.1h using avrdude - the board has Arduino bootloader). After flashing new firmware, all settings need to be checked and set back to machine defaults (which you should get before updating firmware). By default, mine came with inverted Y axis (see the mirrored text on the red plywood). This can be fixed by sending $3=2 to GRBL (setting is saved in EEPROM and is stored even after power off). Another thing to mention is that you should double-check all screws, especially the ones from pre-assembled Z axis and spindle. My Z-axis lead screw slipped from motor axis, the spindle couldn't be lifted and I broke the bit. Spindle motor RPM is another unknown thing about these machines, and I'm thinking of measuring it. Last, use a grease spray and lubricate lead screws and linear rods. It is also important to keep these parts clean.

Comments (5)Show Original -

04/03/2020

All right, I got it. Thanks! The trial may come.

CommentsShow Original -

19/02/2020

The packaging was really well done, no damaged part or even scratches, only a few missing screws. Assembly was a bress, I used a video for the first part, but just followed the instructions after about 30 minutes. It took only 2-3 to assemble and was really intuitive. The GRBL software then comes with the machine isn't the best but works for a few test cuts with the test files. Overall quality is good and for the very low price, it's a really good buy. The cutting quality is very good, but the bits provided aren't for much more then engraving and small detailed jobs.

CommentsShow Original -

13/10/2020

Great game. Works the way it's supposed to. Good to have some spares with me ❤ The assembly instructions could be a little better.

CommentsShow Original -

philippeVIP4FR28/01/2020

philippeVIP4FR28/01/2020Very well packed complete Problem: Engine x left motor axis ER11 does not fit with the nozzle Axis too big The tool door does n't this screw the card to a problem does not work

Comments (1)Show Original -

21/08/2020

Is fine. Good product.

CommentsShow Original -

16/01/2022

Came 3 weeks earlier as announced. Some parts are different, but I guess, better, as the controller board (see picture). Some wireing is different to the description (paper version. I haven't read the online). Someone who is able to assemble IKEA parts should have no problem with this kit and if someone has problems, I'm not sure whether he/she should use it. For me it's a door to a new dimension, as my experiences are more from woodworking with a precision of about 1mm. This is working with precision below 0.01mm. Therefore it's an engraver, not a cutter. Don't expect something else. My first mission was driling holes for a PCB at the correct position. It moves the task more to programming, but dealing with inch (std pcb: 1/10inch) and mm (for some parts) is not easy. With this kit the result became precice, predictable and reproducable. That's why I wanted this kit. I used just the offline mode (sd card) so far and I currently see no reason to plug it to my PC, installing driver,software, ... especially, because it's a very old one.

CommentsShow Original -

TITANICVIP3DE05/01/2022

TITANICVIP3DE05/01/2022fast delivery .looks good just need to test

CommentsShow Original -

04/03/2020

arrived in 1 mouth, package looks good , some screws are not in their bag, still not assemble

CommentsShow Original

![[BR Direct] TWOTREES TTC450 CNC Laser Engraver Wood CNC Router Milling Cutting Machine Laser Engraving Machine For Acrylic PCB PVC Metal](https://imgaz3.staticbg.com/thumb/grid/oaupload/banggood/images/A2/18/8437cc28-bc60-4dee-a70e-685b41bd3489.jpg)

![[EU Direct] TWOTREES TTC450 CNC Laser Engraver Wood CNC Router Milling Cutting Machine Laser Engraving Machine For Acrylic PCB PVC Metal](https://imgaz.staticbg.com/thumb/grid/oaupload/banggood/images/93/B8/52a6f40a-38dd-4038-96dc-f914537166e6.jpg)

![[EU/US Direct]TRONXY® Marker 40 5.5W DIY Laser Engraver CNC Laser Engraving Cutting Machine Desktop Carving Machine Eye Protection 420x400mm](https://imgaz2.staticbg.com/thumb/grid/oaupload/banggood/images/4B/D5/3b35a282-0050-466f-ac5c-d06b0fa22046.png)

![[EU Only]TWOTREES Brushless Spindle Motor 500W Clamps Air Cooled Spindle 500W CNC Spindle Motor + Power Supply Speed Governor For Engraving](https://imgaz3.staticbg.com/thumb/grid/oaupload/banggood/images/7F/79/6ea87106-ca15-4060-b47c-1bf27127ba90.jpg)

![[EU/US Direct] SCULPFUN S9 Laser Engraving Machine Laser Beam Shaping Technology High-precision Wood Acrylic Laser Engraver Cutting Machine 410x420mm Engraving Area Full Metal Structure Quick Assembly Design](https://imgaz.staticbg.com/thumb/grid/oaupload/banggood/images/96/18/7d36d6dd-8e39-43ae-b4bc-31cd49ff1c27.jpg)

![[EU/UK/US/AU/MX Direct]TWOTREES® 10W TTS-10 PRO Laser Engraver Upgraded Totem S Engraving Machine 300x300mm Engraving Area 10W Laser Module APP Connection Remote Control](https://imgaz2.staticbg.com/thumb/grid/oaupload/banggood/images/D3/8A/2f8a67e2-2ce6-4e1b-a8eb-9fcf1d50235c.jpg)

![[EU/US DIRECT] ATOMSTACK P7 M30 Portable Laser Engraving Machine Cutter Wood Cutting Single Arm Laser Engraver Eye Protection Metal Engraving](https://imgaz.staticbg.com/thumb/grid/oaupload/banggood/images/52/2D/a5b30cd7-c034-4583-a83a-a8280f749111.jpg)

![[EU/US Direct]LONGER Laser Rotary Roller, 6-200mm Engraving Diameter, 360 Degree Rotating, Engrave on Cylindrical Objects, Goblets, Pen, Pipes](https://imgaz3.staticbg.com/thumb/grid/oaupload/banggood/images/7E/12/97c73028-b69d-40d2-b967-023aec91de86.jpg)

![[EU/US/UK/MX Direct] TWOTREES® TS2 Laser Engraver Professional Laser Engraving Machine 450mm*450mm Large Engraving Area 10W Laser Power APP Connection Auto Focus](https://imgaz2.staticbg.com/thumb/grid/oaupload/banggood/images/1E/59/0e7b0f9d-f5d4-4e89-8f6a-01d9acd181b2.jpg)

![[EU/US Direct] xTool D1 Pro 20W Laser Engraver All-in-1 Kit](https://imgaz2.staticbg.com/thumb/grid/oaupload/banggood/images/53/6E/6abcca57-19b5-4024-8c68-2c4a33470424.png)

![[ US/CZ/UK/AU/MX Direct] TWOTREES® TTS-55 PRO Laser Engraver Upgraded Totem S 40W Engraving Machine 300x300mm Engraving Area 5.5W Laser Module APP Connection Remote Control](https://imgaz3.staticbg.com/thumb/grid/oaupload/banggood/images/AC/12/781dc7c1-fcc0-4e5c-9ea3-44f7755bfb97.jpg)

![[EU/US Direct] xTool D1 Pro 10W Laser Engraver Higher Accuracy Diode DIY Cutting Machine](https://imgaz2.staticbg.com/thumb/grid/oaupload/banggood/images/FA/6C/76f9d935-b22c-4e7d-891e-3fb226d9f091.jpg)

![[BR Direct]SCULPFUN S9 Laser Engraving Machine Ultra-light Laser Beam Shaping Technology High-precision Wood Acrylic Laser Engraver Cutting Machine 410x420mm Engraving Area Full Metal Structure Quick Assembly Design](https://imgaz.staticbg.com/thumb/grid/oaupload/banggood/images/9F/86/80f2c35d-3218-4203-8733-914b8407e0fd.jpg)

![[EU/US Direct] LONGER RAY5 5.5W Laser Engraver 3.5inch Touch Screen Offline Carving Ultrafine Focused Laser 32-Bit Chipset, Upgradable Laser Module](https://imgaz1.staticbg.com/thumb/grid/oaupload/banggood/images/06/D1/91a3d1da-3553-4936-84d2-c29965700412.jpg)

![[US Direct] ATOMSTACK P9 M40 Portable Dual Laser Engraving Cutting Machine 5.5W Output Power DIY Laser Engraver](https://imgaz1.staticbg.com/thumb/grid/oaupload/banggood/images/15/2C/49e42c77-fdbd-4573-af19-19983cee70ae.jpg)

![[EU/US Direct] LONGER RAY5 10W Laser Engraver 0.06x0.06mm Laser Spot Air Assist Touch Screen Offline Carving 32-Bit Chipset WiFi Connection Working Area 400x400mm](https://imgaz2.staticbg.com/thumb/grid/oaupload/banggood/images/DA/0B/5aac47fe-0237-4e4e-842f-1a3d05921d76.jpg)

![[EU/US Direct] ATOMSTACK A5 PRO Laser Engraving Machine Cutter Wood Cutting Design Desktop DIY Laser Engraver New Eye Protection Design Ultra-Fine Laser Focal Area](https://imgaz.staticbg.com/thumb/grid/oaupload/banggood/images/86/52/412f1b0b-a4c7-49a8-a36d-1984d34eaefc.jpg)

![[BR Direct] SCULPFUN S30 5W Laser Engraver Cutter Automatic Air-assist 0.06x0.06mm Laser Focus 32-bit Motherboard Replaceable Lens 410x400mm Engraving Area support Expandable 935x905mm](https://imgaz1.staticbg.com/thumb/grid/oaupload/banggood/images/C2/04/eab1ef8f-b729-4a58-baf0-4549487365fe.jpg)

![[BR/AU Direct]TWOTREES® 400*400mm Laser Engraver Honeycomb Working Table Board Platform for Laser Engraving Cutting Machine 400x400x22mm](https://imgaz2.staticbg.com/thumb/grid/oaupload/banggood/images/10/B3/dc111833-4f37-4a20-b105-add2988ea6bd.jpg)

![[EU/US Direct] xTool D1 Pro 20W Desktop Laser Engraver Cutting Machine With RA2 Pro With 8Pcs Risers](https://imgaz2.staticbg.com/thumb/grid/oaupload/banggood/images/B7/5A/5ab2049c-73db-4bab-8ac6-7a68d89c5fc9.jpg)

![[AU Direct]TWOTREES® Automatic Roller Engraving Module For Totem S Laser Master Engraving Cylindrical Objects Cans Models Rotary Roller Adjustable Width](https://imgaz3.staticbg.com/thumb/grid/oaupload/banggood/images/C5/66/c2267dcd-0a26-4031-aec2-75bb536fc5d0.jpg)

![[BR Direct] TwoTrees TTS-20 Pro 130W High Speed Laser Engraver CNC Support Offline Engraving Metal 20W Powerful Laser Engraving Machine With Airpump&Honeycomb](https://imgaz.staticbg.com/thumb/grid/oaupload/banggood/images/FF/91/488b5c08-f3a4-4f46-96e9-6b9cc02cefa5.jpg)

![[BR Direct] TWOTREES® 10W TTS-10 Laser Engraver Upgraded Totem S Engraving Machine 300x300mm Engraving Area 10W Laser Module APP Connection Remote Control](https://imgaz2.staticbg.com/thumb/grid/oaupload/banggood/images/77/E4/873fd349-f2f5-4c00-998f-019f8efdac27.jpg)

![[CL Direct] TWOTREES® TTS-55 Laser Engraver Upgraded Totem S 40W Engraving Machine 300x300mm Engraving Area 5.5W Laser Module APP Connection Remote Control](https://imgaz1.staticbg.com/thumb/grid/oaupload/banggood/images/08/36/62884a1c-4fcc-4a36-a779-1f2b1220f7f1.jpg)

![[CL Direct]TWOTREES® 10W TTS-10 pro Laser Engraver Upgraded Totem S Engraving Machine 300x300mm Engraving Area 10W Laser Module APP Connection Remote Control](https://imgaz1.staticbg.com/thumb/grid/oaupload/banggood/images/66/D3/afaaaa7a-97e4-453b-ab84-62428a461307.jpg)

![[EU/US Direct] ACMER P2 10W Laser Engraver DIY Engraving Machine Fixed Focus Engraving at 30000mm/min Ultra-silent Auto Air Assist](https://imgaz1.staticbg.com/thumb/grid/oaupload/banggood/images/13/E2/4ba25d2e-9298-4fe3-9b69-489667f34f29.jpg)

![[BR Direct] TWOTREES® TTS-55 PRO Laser Engraver Upgraded Totem S 40W Engraving Machine 300x300mm Engraving Area 5.5W Laser Module APP Connection Remote Control](https://imgaz1.staticbg.com/thumb/grid/oaupload/banggood/images/12/BF/d74d2299-04f5-4e57-a635-bf9d80d42152.jpg)

![[EU/US Direct]SCULPFUN S30 5W Laser Engraver Cutter Automatic Air-assist 0.06x0.06mm Laser Focus 32-bit Motherboard Replaceable Lens 410x400mm Engraving Area support Expandable 935x905mm](https://imgaz3.staticbg.com/thumb/grid/oaupload/banggood/images/3F/44/118adfa7-ba90-477e-b01d-aa06db93a23b.jpg)